Our net-zero journey

Our CO2 footprinT

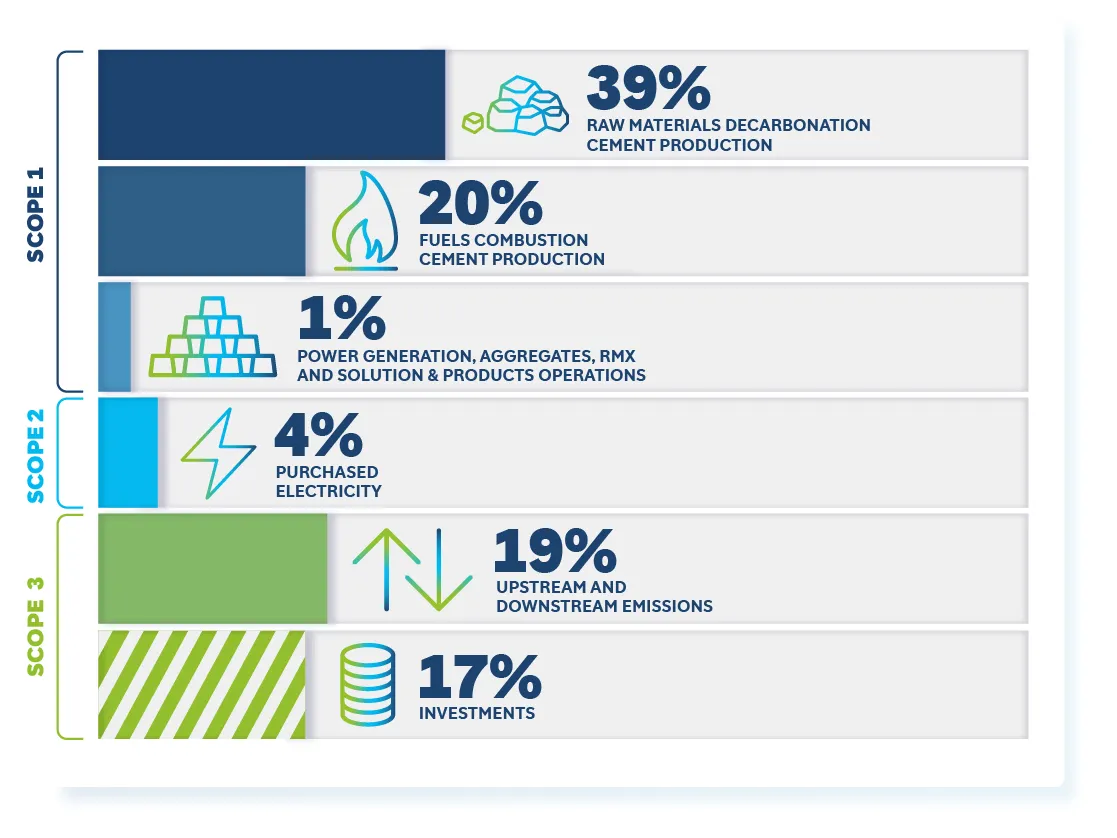

Scope 1 emissions – released directly from our operations – account for 60% of our footprint and are at the core of our emissions reduction strategy. Most of these emissions come from cement production. 39% are generated during the decarbonation of the raw materials we use to produce clinker, and fuel consumption necessary to heat cement kilns is another significant source of emissions. A small share of scope 1 emissions come from operations linked to Solutions & Products, aggregates and ready-mix concrete.

Scope 2 emissions account for 4% of our carbon footprint. These include indirect emissions from the generation of purchased electricity consumed by our owned or controlled equipment.

Scope 3 emissions account for 36% of our carbon footprint. These include all other indirect emissions generated in our supply chain, such as for transportation and the extraction and production of purchased materials and fuels. Scope 3 also includes direct emissions from non-consolidated companies and investments.

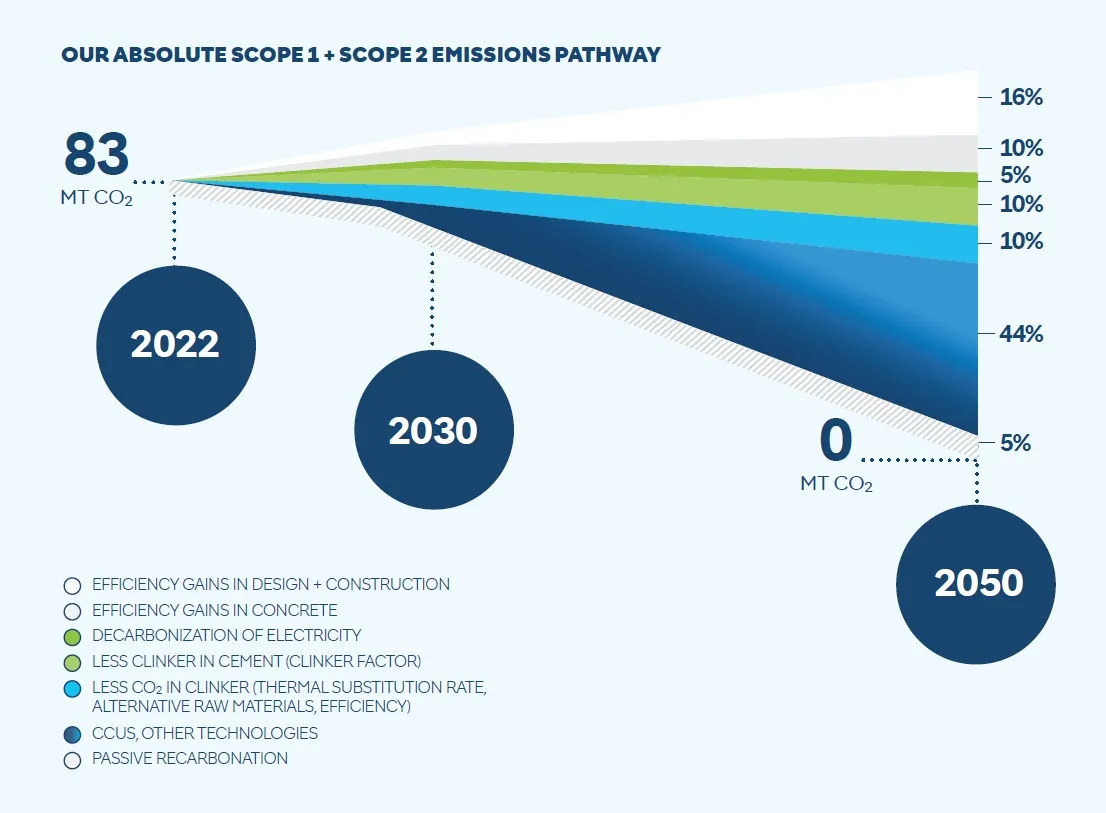

OUR PATHWAY TO NET ZERO

Our pathway to 2030 is clear. Increasing focus on embodied carbon per m2 of building is expected to move the market to more carbon-efficient construction. We will support this transition with our low-carbon products as well as enabling smart design systems like 3D printing that will support the progressive optimization of the structural elements, creating the same functional units with less material.

Additionally, we will reduce our clinker factor, use alternative fuels instead of fossil fuels, increasing our thermal substitution rate and our use of renewable energy. We will invest in proven technologies that produce positive returns. The pathway from 2030 to 2050 leverages the same levers used between 2020 and 2030, while integrating new and advanced technologies. These technologies include novel binders and CCUS.

Our reduction ambitions

Holcim is committed to taking the following strategic actions to achieve net zero in our scope 1 emissions:

ENERGY EFFICIENCY

Promoting carbon efficiency by reducing the amount of concrete or cement required per square meter of construction.

ALTERNATIVE RAW MATERIALS

Substituting waste materials and by-products from other industries for raw materials in the production process.

CLINKER FACTOR

Replacing clinker with alternative mineral components to reduce the carbon intensity of our cement products.

ALTERNATIVE FUELS

Using pretreated non-recyclable and biomass waste fuels instead of fossil fuels in cement kiln operations.

CCUS AND OTHER TECHNOLOGIES

Deploying large-scale carbon capture solutions in partnership with leaders in various sectors.

A range of factors are involved in reducing our scope 2 emissions to net zero:

SOLAR AND WIND POWER

Our efforts to maximize the use of green energy in our plants includes those we operate ourselves. The installation of solar panels at our Hagerstown plant in Maryland enabled us to generate 10 MW, saving the equivalent of over 12,000 tons of CO2. We’ve installed three wind turbines at our Paulding plant in the US which eliminates the equivalent of 9,000 tons of CO2 per year.

WASTE HEAT RECOVERY

Repurposing excess heat from cement kilns to generate electricity, with plans to triple the number of waste heat recovery units we own by 2030.

POWER PURCHASE AGREEMENTS

We will continue to expand our renewable energy portfolio by collaborating with offsite power producers.

With our scope 3 intermediate targets validated by SBTi, we are prioritizing the following actions to reduce emissions in this category:

DOWNSTREAM TRANSPORTATION

- Optimizing routes and loads

- Prioritizing waterways and rail over road transport

- Training drivers to improve road safety and reduce fuel consumption

- Gradually replacing diesel with eco-friendly fuels

FUELS AND ENERGY

Replacing traditional fossil fuels with locally sourced, alternative and non-extractive fuels derived from waste.

PURCHASED CLINKER AND CEMENT

Requiring CO2 information from our clinker and cement suppliers to facilitate purchase of low-carbon products.

OTHER PRODUCTS AND SERVICES

- Integrating CO2 requirements into the tendering process

- Eliminating the use of carbon-intensive fuels through innovative technologies such as autonomous electric haulers

%20(2).jpg9bb5.webp?itok=KXmizOpK)