Building better with less

At Holcim, we are building better with less to decarbonize construction.

LOW-CARBON BUILDING

WE ARE MAKING SUSTAINABLE CONSTRUCTION POSSIBLE AT SCALE AROUND THE WORLD – FROM ZURICH TO NEW YORK AND MEXICO TO MANILA – WITH OUR INNOVATIVE AND SUSTAINABLE BUILDING SOLUTIONS.

Since concrete is infinitely recyclable, versatile and resilient, we are continually innovating to make low-carbon concrete the building material for a net-zero future. Our ECOPact concrete offers significant CO2 reductions without compromising on performance. Our lower-carbon, circular solutions reduce buildings’ carbon footprint and strive to have a positive impact on nature and the surrounding environment.

As the world’s broadest range of low-carbon concrete, ECOPact delivers 100% performance offering at least 30% lower CO2 emissions compared to standard concrete.

When permitted by regulations, ECOPact can include recycled construction and demolition materials, further closing the resource loop. ECOPact is making buildings greener around the world, from the LEED-certified Boston University Data Science Center to the Arca building in Milan, affordable housing in Ecuador and one of London’s latest green neighborhoods, the Eight Gardens complex.

Our ECOPlanet range of low-carbon cement includes the world’s first cement with 20% recycled construction and demolition materials inside.

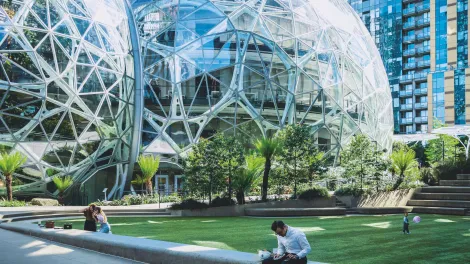

Offered in 27 markets, ECOPlanet is helping to decarbonize buildings worldwide, from the iconic LEED Gold-certified Spheres in Seattle to the Al-Ain El-Sokhna Port extension in Egypt. By helping us build better with less, ECOPlanet is playing a key role in meeting the needs of population growth and urbanization.

SMART DESIGN

We are empowering smart design to use minimum materials for maximum strength like 3D printing that can use up to 50% fewer materials with no compromise in performance.

We make this possible with our proprietary technologies from our proprietary 3D concrete printing ink TectorPrint, to our ultimate performance concrete, DYNAMax.

DYNAMax is our ultimate high-performance concrete for demanding construction projects. It enables smart design by optimizing material used in every new building and unlocking more usable space, from the BREEAM-certified Miro office complex in Romania to the Seven Gardens Oak House in Germany. It boasts incredible durability leading to reduced building maintenance and lifecycle costs, a sustainable footprint driven by reduced material use, local production and short transport routes, and a circular and fully recyclable profile.

Striatus is a first-of-its-kind 3D concrete printed footbridge. Designed by Zaha Hadid architects and ETH’s Block Research Group in collaboration with incremental 3D, it was made possible by Holcim’s proprietary ink, TectorPrint. It establishes a new language for concrete that is digital, environmentally advanced and circular by design.

The structure is composed of 3D concrete printed blocks that stand together solely through compression, with no reinforcements, no glue and no binders, applying computational design and 3D printing for minimal material use and maximum strength. All the blocks are entirely recyclable. Striatus has received numerous architecture awards from the 2022 World Architecture Community Awards to the 2022 Rethinking The Future Architecture Award.

One of our breakthrough innovations to help the world build better with less using smart design is carbon prestressed concrete (CPC). Using high-strength concrete reinforced with prestressed carbon fibers, CPC slabs use a proprietary process and patented technology that gives them the same load-bearing capacity as traditional reinforced concrete slabs while being up to five times thinner and lighter. In addition to enabling resource-efficient construction systems, the absence of steel means extending its service life up to 100 years, at the end of which the CPC systems can be disassembled and reused or fully recycled.

We recently used CPC to build a footbridge in Switzerland. With timber, this nine-meter span would weigh 26 tons. With CPC, the same footbridge weighs an extremely low 14 tons. That’s 46 percent less than timber.

Digitalization

We are optimizing material use and reducing waste through digital solutions.

Our digital tools enable stakeholders in the construction value chain to make more sustainable decisions.

ConcreteDirect is the industry’s leading ready-mix management platform for more efficient, safer and environmentally friendly concrete use at every jobsite. It offers real-time data on truck location and status, e-tickets, delivery and product performance and Environmental Product Declarations (EPDs), enabling increased transparency and efficiency and reducing waste and material use.

Holcim Digital Concrete Services uses numerical simulations and sensors to help contractors and engineers build smarter with concrete – reducing time, costs, uncertainty and environmental impact in the construction process. Across all regions, Holcim currently offers SMARTherm, SMARTCast and SMARTFlow services that enable improved efficiency.